Custom Search

With the evolution of modern process plants, the analog pressure transmitter and pressure gauges have become very useful piece of instruments for transmitting pressure or for local indication by the pressure gauge. Often times it is required to calibrate these devices. What do you actually need to do this?

Well if you have a pressure calibrator, you might just be able to calibrate your device. In this post, the use of the fluke pressure calibrator to calibrate a pressure transmitter is discussed. Please read on:

The Fluke 718 Pressure Calibrator:

Use of the Fluke Pressure Calibrator:

The pressure calibrator or generator carries out the following operations:

- Calibration of pressure transmitters

- Measuring of the pressure applied to a 1/8’’ NPT connection.

- Generation of a pressure

- The unit can measure current of up to 24mA depending on the model

The pressure calibrator indicates pressure on a 5-digit display in the following units: psi, inH2O at 4°C, inH2O at 20°C, kPa, cmH2O at 4°C, cmH2O at 20°C, bar, mbar, kg/cm²,inHg and mmHg. This device is very convenient when you need to check a pressure gauge or a pressure transmitter on-site.

Before using the fluke 718 pressure calibrator or higher models, please adhere to these safety instruction:

- Replace the fuel cell immediately the battery cell status indicator appears to display incorrect indications liable to represent risks of electrocution or bodily injury.

- Should a pressurized circuit suddenly decompress, cut the valve and gradually lower the pressure before disconnecting or connecting the pressure sensor.

- Do not apply pressure which exceeds the operating limits of the Fluke 718 device to avoid damage due to overpressure.

- Do not apply torque between the pressure connection and the calibrator case to avoid causing mechanical damage to the calibrator.

- Only use non-corrosive gas and dry air to avoid damaging the pump. Check the continuity of measuring leads prior to use. Inspect the calibrator for cracks or any damage

Fluke 718 Pressure Calibrator Functions:

The diagram below illustrates the basics of the pressure calibrator:

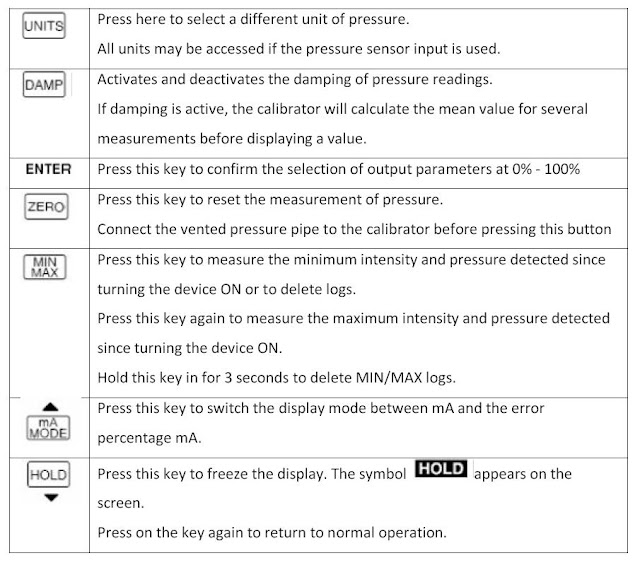

Buttons and Functions on the Fluke 718 Pressure Calibrator:

We can calibrate a pressure transmitter with the aid of the pressure calibrator using the internal pump provided within the generator or with the aid of an external pressure module e.g a hydraulic pump

How to Calibrate a Pressure Transmitter with the Fluke Pressure Calibrator and Its Internal Pump:

To use the pump, simply push the internal pump shaft in and out as shown in the diagram below:

Use the fine adjustment wheel to set the exact pressure you wish to inject.

To calibrate the pressure transmitter with the calibrator, follow the steps below:

Step 1:

Release the pressure and drain the process line before connecting the pressure calibrator.

Step 2:

Connect the pressure transmitter to the internal sensor of the calibrator as shown below:

Step 3:

Ensure that the pressure/vacuum switch is set to the desired position. Turn the switch forwards (clockwise) to apply pressure and backwards (anti-clockwise) to create a vacuum.

Step 4:

Turn the pressure/vacuum regulator (anti-clockwise) to evacuate all the pressure/vacuum in the pump.

Step 5:

Press ZERO to reset the pressure measurement

Step 6:

Set the fine adjustment button to the intermediate span

Step 7:

Adjust the pressure/vacuum regulator forwards (clockwise) to close the evacuation valve

Step 8:

Push the pump shaft in and out to apply larger increases in pressure or vacuum. Reduce this movement to apply smaller increases in vacuum/pressure. In this way, various values of input pressure can be applied to your pressure transmitter. Use the fine adjustment button if there is the need for very small changes in pressure/vacuum(Step 9 below)

Step 9:

Use the fine adjustment button to apply very small changes in vacuum/pressure. This button enables the total volume to be adjusted using a small internal tank in the pressure calibrator. With higher external vacuum/pressure volumes, this command adjusts the vacuum or pressure within a limited interval

Step 10:

When you are done, release the pressure in the circuit before disconnecting the pressurized line.

Calibrating a Pressure Transmitter with the Fluke Pressure Calibrator and an External Pump:

To do the calibration, an external pump module is used. This is convenient if the internal calibrator pump is not operational, in which case a small hydraulic pump can be connected to the pressure input point on the generator as shown below:

Then follow steps 1 – 10 outlined for the case of using the internal pump of the pressure calibrator.